Our Products

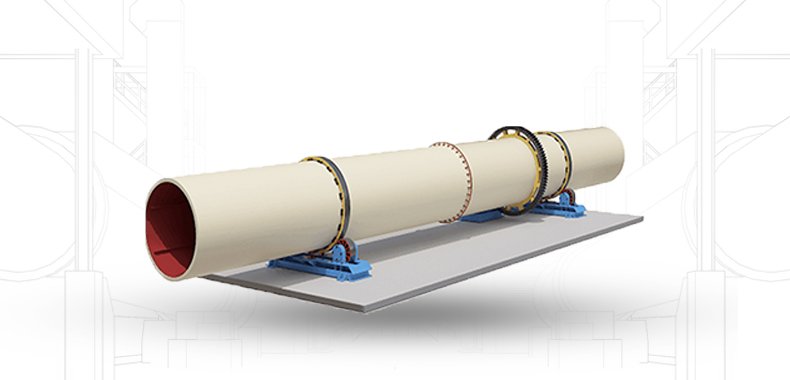

Rotary Dryer

At BM Industries, we offer high-quality Rotary Dryers designed to efficiently dry materials in various industries such as mining, agriculture, chemicals, and pharmaceuticals. Our rotary dryers are built for durability, energy efficiency, and continuous operation, making them a perfect solution for large-scale drying needs.

What is a Rotary Dryer?

A rotary dryer is a cylindrical device that rotates to convey material through a heated air stream, facilitating the drying process. It is ideal for drying granular or bulk materials like ores, aggregates, and food products.

Key Features

- Available in direct and indirect heating models

- Customizable drum size and configuration

- Energy-efficient design with low operational cost

- Corrosion-resistant construction for extended lifespan

- Adjustable speed, temperature, and airflow control

- Capacity: from 500 kg/hr to 50,000 kg/hr

Applications

- Mining and Mineral Processing

- Agricultural Products and Fertilizer Drying

- Chemical and Pharmaceutical Industries

- Food Processing (Grains, Fruits, Vegetables)

- Waste Treatment and Recycling

Customization Options

- Jacketed Drums for Steam or Thermal Oil Heating

- Variable Speed Drives for Optimized Drying

- Customized Lifters and Internal Configurations

- Automatic Feeding and Discharge Systems

- Integration with Process Control Systems

Quality & Compliance

Our rotary dryers are engineered for durability and compliance:

- Design as per API, ASME, and IS standards

- Non-destructive testing of welds

- Performance testing with actual materials

- Comprehensive documentation and inspection reports

Why Choose Us?

- 40+ years of rotary drying technology experience

- Customized solutions for maximum drying efficiency

- Robust and easy-to-maintain equipment

- Excellent after-sales and technical support

Equipments

- Rotating Drum with Internal Lifters

- Support Rollers and Drive Assembly

- Hot Air Generator or Heating Chamber

- Cyclone Separator and ID Fan

- Dust Collector / Bag Filter System

- Feeding and Discharge Conveyors

Design & Construction

- Design: Based on drying rate, material flow, and moisture content

- Insulation: Rockwool or Glasswool for thermal efficiency

- Finish: Painted or corrosion-resistant coated

- Controls: Temperature, RPM, and exhaust flow control system

Contact Us

Get in Touch with BM Industries

Have a question, need a custom quote, or want to discuss your project requirements? Our team is here to help. Reach out to us for expert guidance, quick support, and reliable solutions.