Our Products

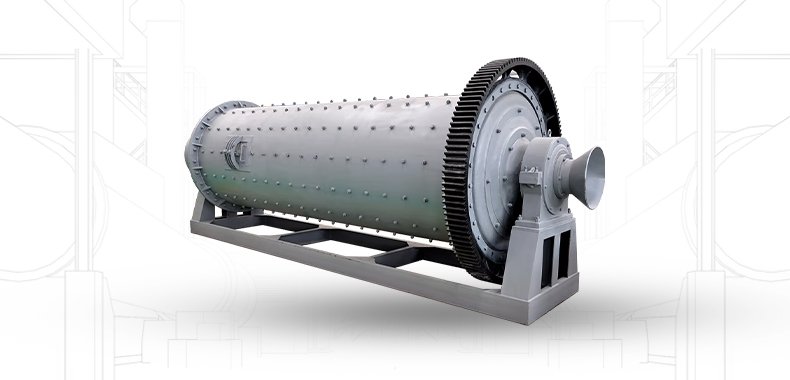

Ball Mill

At BM Industries, we manufacture high-performance Ball Mills engineered for efficient grinding and mixing of materials in various industries. Our ball mills are robust, low-maintenance, and ideal for use in mineral processing, cement production, paint manufacturing, ceramics, and more.

What is a Ball Mill?

A ball mill is a cylindrical device used to grind or blend materials using steel or ceramic balls that rotate within the drum. The rotation causes impact and attrition, making it suitable for both dry and wet grinding processes.

Key Features

- Fabricated using high-grade mild steel or stainless steel

- Available in batch and continuous operation types

- High efficiency with uniform particle size reduction

- Options for dry or wet grinding

- Customizable drum size, lining, and drive system

- Capacity: from 50 kg to 10,000 kg per batch

Applications

- Mineral Processing & Ore Grinding

- Cement & Building Materials

- Paints & Pigment Manufacturing

- Ceramics & Refractories

- Pharmaceuticals & Chemicals

Customization Options

- Open or Closed Circuit Design

- Feeding & Discharge Mechanism Customization

- Jacketed Design for Heating/Cooling

- Auto Feeding & Dust Collection Systems

- Control Panel Integration (Semi/Auto)

Quality & Compliance

Our ball mills are designed and tested to meet industrial standards:

- Sturdy structural construction

- Precision-balanced rotating assembly

- Hydro & load testing (as required)

- Material traceability and MTCs (if required)

Why Choose Us?

- 40+ years of mechanical fabrication experience

- Custom-built machines for specific process needs

- Reliable operation with minimal maintenance

- Strong after-sales support and spare availability

Equipments

- Rotary Drum with Liners (Rubber/Steel)

- Heavy-Duty Trunnion or End Shaft Mounting

- Gearbox and Motor Assembly with VFD

- Feeding Hopper & Discharge Valve

- Temperature Monitoring (Optional)

- Frame/Base with Vibration Isolation

Design & Construction

- Design Code: IS Standards, customized to application

- Shell Thickness: As per grinding load and capacity

- Drum Finish: Painted, Epoxy Coated, or SS Polish (internal)

- Ball Charging Port: Manual or Pneumatic

- Optional Accessories: Dust Collector, Cyclone Separator

Contact Us

Get in Touch with BM Industries

Have a question, need a custom quote, or want to discuss your project requirements? Our team is here to help. Reach out to us for expert guidance, quick support, and reliable solutions.